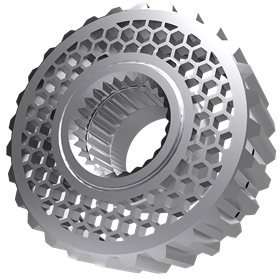

The Best Of 3D Printing that You Can Think Of

Every beginner solves a dilemma at the beginning of choosing the right 3D printer that suits him. Here’s a complete guide to choosing a 3D printer. With the best quality 3d printing metal powder you can now come up with the best options.

What is 3D printing?

3D printing is a process during which a physical model is created based on the so-called digital 3D model designed e.g. in CAD. Printing is most often done by melting fiber or plastic and then applying it in layers to the final shape according to the digital template.

Terminology: Filament

It is the material from which the printer prints the resulting product. Most often the filament is made of plastic PLA or ABS. The plastic is melted and then applied in layers to the final product form. Extruder or, the print head is the part of the printer that consists of a nozzle, a material feed mechanism, and a fan.

Nozzle

It is the part of the extruder from which the fused fiber is extruded onto a support.

Base (bed)

It serves as the surface on which the product is printed.

Heated washer

It is used for better adhesion of materials. It is generally better to use a heated mat. E.g. for ABS, the material expands if you do not have a heated mat.

RepRap

Open source 3D printers free to use.

G-code

Coordinates (X, Y, and Z) for the printer describing each movement needed to produce an object.

Slic3R

Software used to convert and edit 3D models to G-code.

Axis

It is reference line for movement. The 3-axis machine can move in the X (left to right), Y (front and rear) and Z (up and down) directions.

Carriage

The movable part on which the washer is usually located

Engine

All extruders and axes have motors to move the printer.

Materials: filament

Filament is available in different colors

PLA

It is a biodegradable polyester product made of plant materials. It is most often used for 3D printing because it is biologically feasible and can be melted at 60 degrees Celsius. PLA is prone to clogging. Therefore all manufacturers’ recommendations must be followed.

ABS

It is an amorphous thermoplastic industrial copolymer that is resistant to mechanical damage. The factors are rigid, tough, low and high-temperature-resistant, low-absorbent, depending on type. However, it is made from oil and produces harmful fumes during melting, and it is therefore necessary to have ventilation turned on when printing. Lego blocks are made of ABS. It has poor adhesion, so a heated pad is required for printing.

FIVE

Polyethylene terephthalate is a thermoplastic from the group of polyesters. It is mainly known for the fact that it is made of most plastic bottles for drinks. It gained great popularity in printing because it is very strong, stable, has low thermal expansion. He takes good ABS and PLA properties and leaves them negative. It is usually slightly more expensive than PLA and ABS.

LAYWOOD

It is PLA with wood. The resulting print does not look so plastic, but often jams. Temperature and print speed affect the resulting color.

Pa6 – Polyamide (Nylon)

Tough and flexible material that is not widely used because it requires higher temperatures and not all jets can handle it. It also needs a different surface of the printing pad, such as glass fiber.

3D printing technology

The main technology that provides such prints is FFF, also known as FDM a registered trademark of Stratasys. Unfortunately, it will not handle the resolution usable for example for the design of classical jewelry. A huge advantage is the variation of the various materials that these printers allow, as well as the ever-active development of new materials.